UNISUNX You Can Rely on

Join us for UNISUNX Global Network for sales and service.

Unisunx Since 1988

Discover Unisunx Solutions

Unisunx has become one of the largest bases for manufacturing CNC processing center, precise panel saw, edge banding machines and boring machine in China.

Why choose Unisunx

professional R&D and Production

create value for customers

process management

raw material control

Technology creates value

What's new at Unisunx

Unisunx has become one of the largest bases for manufacturing CNC processing center, precise panel saw, edge banding machines and boring machine in China.

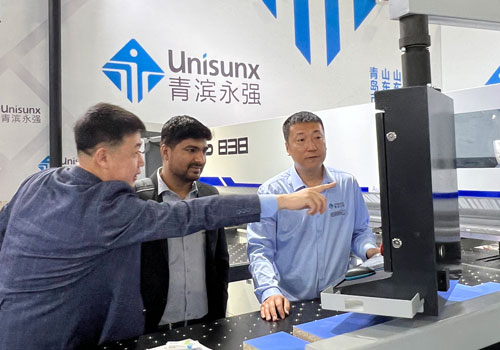

The Shanghai exhibition has come to a successful conclusion

2024-09-25There are actually these precautions about CNC cutting machines in spring!

2024-04-08These small “secrets” that improve the efficiency of CNC cutting machines

2024-03-073 minutes to learn about the industry’s common sense of push table saws

2024-03-07The Qingdao Home Furnishing Industry Association conducted an exclusive interview with our company

2024-03-07Contact Us

Frequently asked questions

Our engineers can work separately according to the requirements of design for clients of the equipment. and send a customer confirmation to help customers to save costs. During the manufacture of the equipment, we photograph product production progress, and sent to the customer to track the progress.

Equipment painting completed before shipment, With Stretch film to avoid rub off the surface paint, It can used wooden cases packaging according to users requirements.(Key parts such as electric cabinet with shockproof packaging material and then packed in wooden cases. )

This is specially designed machine according to your specific requirement. From engineers designing to production completion, it needs about 45-55 days.

We pay much attention to quality control from the very beginning to the end. Each machine is assembled and carefully tested before shipment.

Quality guarantee time is one year. We choose world famous brand components to keep our machine in perfect working condition.

Yes, we supply overseas service, but customers need to pay for the engineers flight tickets and hotel, food.Small machines usually takes 5 days, while big machines usually takes about 20 days.