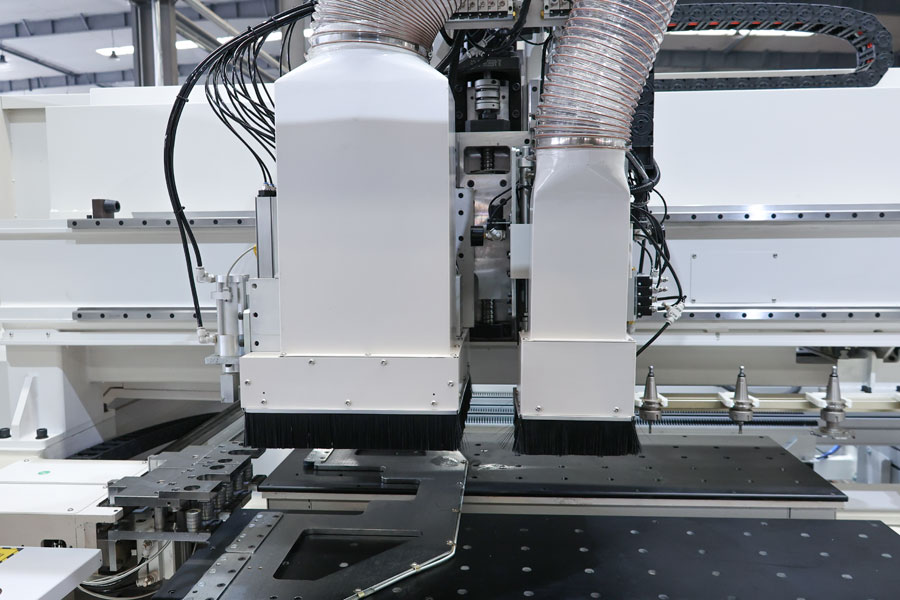

PT6-1325 Six sides drill machine

Mainly used for drilling and grooving of panel furniture

Saving you time is our motivation

Our products include: Panel saw, edge banding machine, reciprocating saw series, over-edging machine, CNC Nesting Machine(CNC Wood Cutting Machine), carving machine series and so forth, which are exported to more than 50 countries and regions, such as Europe, Russia, Southeast Asia, Middle East, North America, Australia. It has established complete sales system (more than 120 dealers). Over yeas of experience in competitions in domestic and overseas markets, our brand has become one of global well-know brand, which offers trustworthy machinery for global customers.

unisunx

Unisunx group company owns 70000 square meters of production scale.

Besides,it has abundant technique strength, full range of testing method and four professional production lines of woodworking machinery.So it can manufacture thousands sets in one month. Our factories locate at Jiaozhou Bay.

The most important highlights at a glance

PT6-1325 Six sides drill machine

- Function introduction:

- Mainly used for drilling and grooving of panel furniture. It can efficiently process common panel furniture two-in-one and three-in-one connector installation holes. At the same time, it can realize panel grooving, milling, standard panel and special-shaped panel. Parts can be processed; this machine automatically recognizes plate information through wireless scanning of plate label, and can automatically feed, automatically process all holes and grooves in one positioning, without turning over, high precision, fast speed, and various processing The board does not need to adjust the machine, the operation is simple, especially suitable for the production and processing of customized furniture;

- Features:

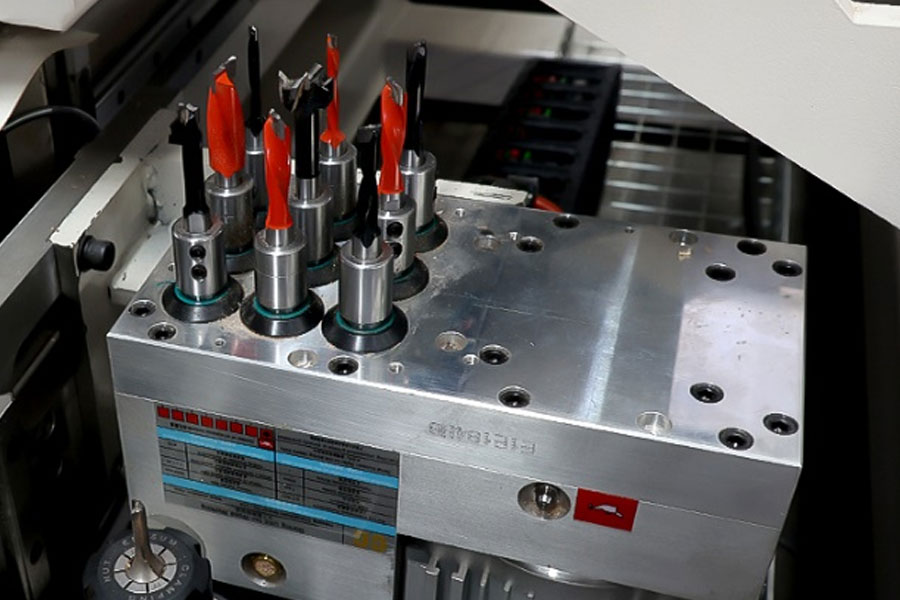

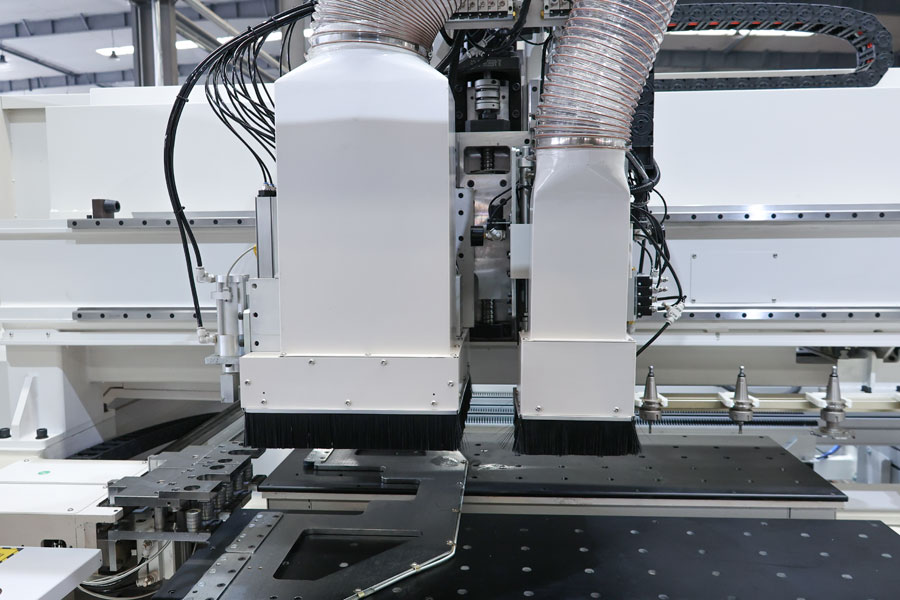

- One-time positioning and multi-face machining accuracy is high, and the machining speed of the up 1 + down 1 CNC drilling package is faster;

- Heavy-duty and high-strength gantry design, high-speed movement of drilling and milling mechanism without jitter, and stable operation of the equipment;

- Can scan codes in batches and automatically queue for processing; you can choose between forward and backward;

- The system integrates CAM software, which is mature and stable, and is convenient for docking with fully automatic production lines;

- 9 sets of absolute value servo drives, which can be accurately controlled, without returning to the origin, without additional travel limit;

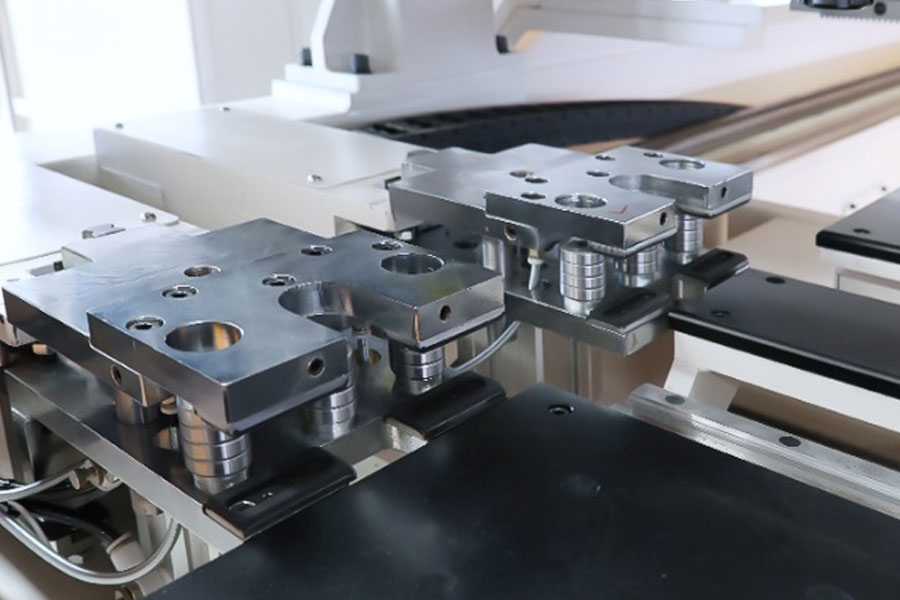

- Intelligent floating clamp intelligent avoidance, large and small plates, and special-shaped plates can be processed; double plates can be processed at the same time; the scientific design of clamp positioning piles reduces the number of clamp switching as much as possible and improves processing efficiency;

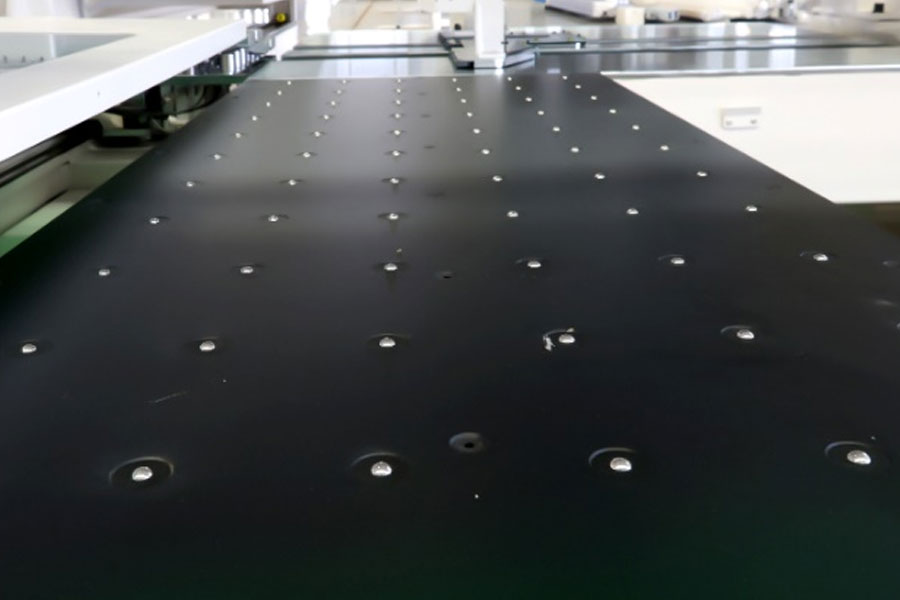

- The air-floating bead countertop can effectively protect the surface of the board and make it easier to load; the electroplated stainless steel countertop in the processing area is stable and not deformed, ensuring the processing accuracy is unchanged;

- It can be used for special-shaped cutting, glass door engraving and milling, with complete functions;

- Computer operation, CAD drawing, CAM import, can directly import DXF, MPR/XML and other open data formats, easy to operate; can be docked with American CV, French Topsolid, Haixun, Sanweijia, Yunxi, 1010 and other well-known domestic and foreign designs Single software.

Technology Data

| serial | PT6 six sides drill machine | |||

| Processing size | X axis travel | 3000mm | Upper Spindle power | 3.5KW |

| Y axis travel | 1500mm | Below spindle power | 3.5KW | |

| Z axis travel | 200mm | Reducer | Japan Shimpo | |

| Maximum feed | X axis speed | 130m/min | Transmission rack | Germany Rotalin |

| Y axis speed | 85m/min | Drive screw | Taiwan TBI | |

| Z axis speed | 25m/min | Frequency converter | Hpmont | |

| Minimum processing size | 40x180mm | Main electrical components | Schneider | |

| Maximum processing size | 1220mm(板宽) | Main pneumatic components | SMC & Airtac | |

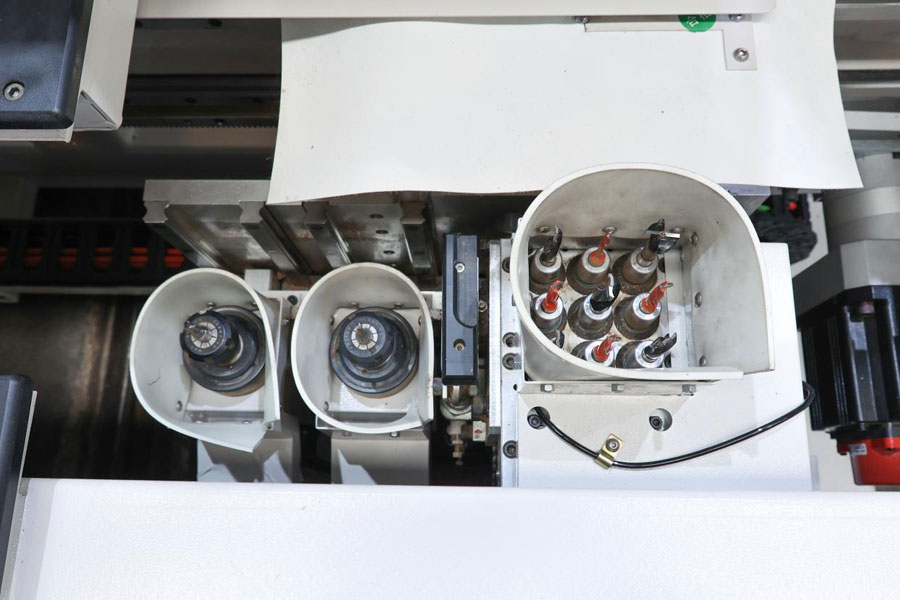

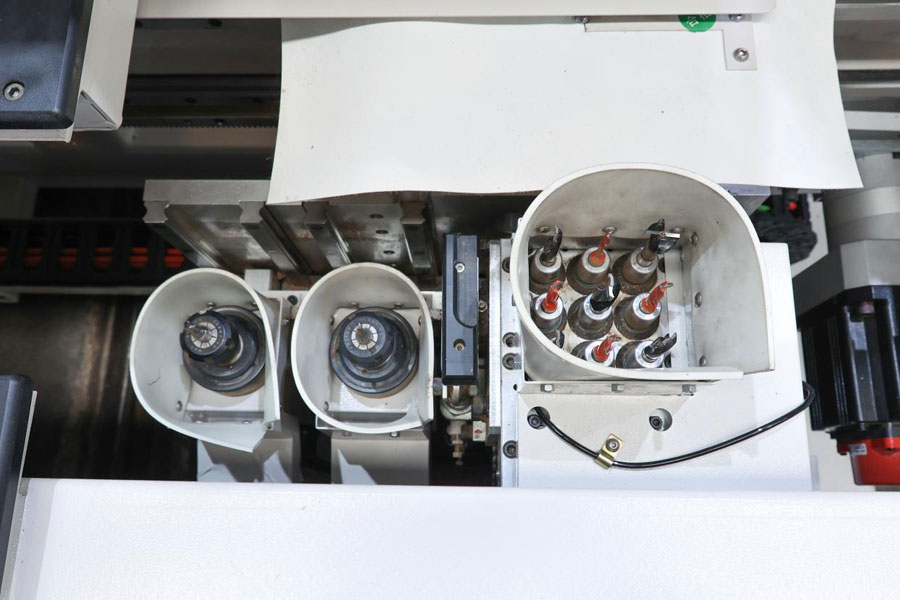

| Upper row drill model | 12V+8H(upper 1) | Wireless scanner | American Zebra | |

| Lower row drill model | 9V(below 1) | Countertop structure | Air Floating Bead Anti-time Special + Chrome Plated Steel Plate | |

| Equipment dimensions | 3050*5700*2600mm | Overall quality | 3800kg | |

| Working voltage, air pressure, power | 3PH AC380V/50Hz、≥0.65Mpa、18.2KW(Does not include electricity for vacuuming) | |||

| other | Double bucket vacuum cleaner, operating instructions, random drills & tools, etc. | |||

| Price | USD | |||