Under the tide of technological intelligence and artificial energy creation, various new products are emerging in the mechanical industry.

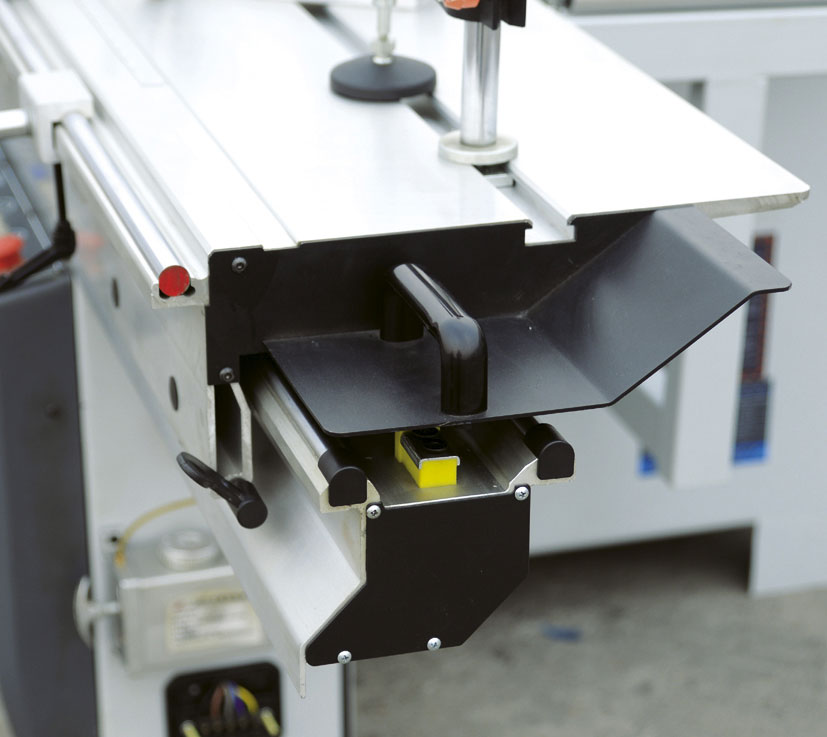

But in almost every production workshop, there will always be the figure of a push table saw. The sliding table saw is a necessary equipment for mass production, standardization, mechanization, and professional production of furniture, which is easy to operate, stable, safe, and efficient.

It plays an indispensable role in the furniture production and manufacturing process.

1、 Precautions for using a sliding table saw

When the equipment is working, the workpiece should be fixed and the profile positioning should conform to the cutting direction to avoid abnormal cutting, avoid applying lateral pressure or curved cutting, ensure smooth cutting, avoid blade impact contact with the workpiece, and the cutting speed should not be too fast to avoid tooth breakage and damage.

In the process of use, if abnormal sound or vibration, rough cutting surface, or odor is found, the operation must be terminated immediately, and the fault must be checked and eliminated in a timely manner to avoid accidents.

During the dry cutting process, prolonged continuous cutting should be avoided to avoid affecting the service life and cutting effect of the saw blade; When cutting wet sheets, water should be added to prevent electric leakage.

- 2、 Small tips for maintaining a sliding table saw

- According to the workload, regular dust removal operations should be carried out inside the push table saw machine to ensure the normal heat dissipation of the motor

- Regularly dust the track to ensure smooth operation of the pushing platform

- Regularly inspect the belt and replace it promptly if any wear is found

- Regularly lubricate the parts of the machine that require lubrication to ensure stable and quiet operation of the equipment